Sheet metal and copper processing and cable assembly - Our contract services

As your reliable partner, we offer you precise sheet metal and copper processing as well as professional cable assembly. With state-of-the-art technology and many years of expertise, we create customized solutions that are precisely tailored to your requirements. Whether simple processing or complex orders – we implement your wishes efficiently and to the highest quality.

Our range of services includes the processing of:

- Sheet metal components, such as mounting plates and housings or housing parts

- Copper bars that we punch, bend or engrave according to your specifications

- Cable assembly, including wire labeling and individual adaptations

Specifically, we offer:

- Holes (with or without thread)

- Breakouts in various shapes and sizes

- Engraving for precise marking

- Customized punching and bending of copper bars

- Cable assembly with individual wire identification and precise wire treatment

Whether small series, custom-made products or complex special solutions – we deliver on time and in top quality. Contact us and let us work together to find the right solution for your project!

Sheet metal processing

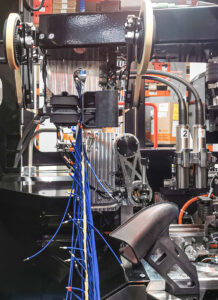

Do you need precise machining of mounting plates, switch cabinet housings and housing parts or other sheet metal parts? We are your competent partner for these tasks. With state-of-the-art technology and specialized machines, we offer you tailor-made solutions for your individual requirements. Particularly noteworthy is our Steinhauer eCAB, which enables us to process sheet metal and control cabinets with maximum precision and efficiency.

Our services include:

- Milling and punching: Precise cutting and punching work – from simple circles or rectangles to complex free contours.

- Bending and forming: Dimensionally accurate bending of sheet metal, e.g. bulkhead plates for switch cabinets.

- Drill holes and threads: We drill holes from 3 mm to 8 mm in diameter and form threads from M4 to M8 – according to your specific requirements.

- Openings and recesses: for cable feed-throughs, the installation of buttons and measuring devices in doors – and much more.

- Installation of accessories: We are also happy to install cable ducts and support rails on your mounting plates and enclosures, thus relieving the strain on your electrical production.

We can process the following materials and workpiece sizes:

- Materials: steel, stainless steel, (copper, aluminum, GRP, plastic)

- Workpieces: from 100×100 mm up to 1,550 ×2,400 mm

Rely on KSV’s expertise for your enclosure and housing processing. Contact us to discuss your requirements and receive a non-binding offer!

Contact person

Marc Winzen

Sales

Phone +49 261 8991 135

Mail marc.winzen@ksv-koblenz.de

Copper processing

Contact person

Marc Winzen

Sales

Phone +49 261 8991 135

Mail marc.winzen@ksv-koblenz.de

With state-of-the-art technology and many years of experience, we offer you first-class solutions in the field of copper processing. On our highly developed machines – the EHRT EB40 and the EHRT FlexPunch – we realize a variety of processing options for copper with the highest precision and efficiency.

Our services include:

- Bending and forming: Our powerful EHRT EB40 bending machine with a bending force of 344 kN enables precise and fast processing of copper parts in a wide range of thicknesses. With a repeat accuracy of 0.2°, we guarantee maximum precision. We offer a variety of bending types, including stack bending, flat bending, upright bending, torsion bending, closed forms and U-bends.

- Punching and nibbling: With our flexible EHRT FlexPunch, we can precisely cut flat copper to length and realize a wide variety of hole patterns, cut-outs or punching with minimal material loss. Machine processing of flat copper with a width of 15 – 200 mm (0.6 – 7.9″) and a thickness of 3 – 16 mm (0.1 – 0.6″) is possible.

Specialization in switchgear systems:

With our two copper processing machines, we can produce almost any copper busbar for the VAMOCON and SIVACON switchgear systems. We offer maximum flexibility in production and mark all workpieces with label printers for precise documentation.

Thanks to our modern machinery, we are able to react with high precision and flexibility to the most diverse requirements in copper processing. From rapid prototyping to small series production – we deliver solutions that are precisely tailored to your needs.

Rely on our expertise when it comes to the precise and efficient processing of copper. Contact us today to discuss your requirements and receive a no-obligation quote!

Cable assembly

In the field of cable assembly and wire printing, we offer you customized solutions for a wide range of applications. With our state-of-the-art Rittal WireTerminal, we guarantee efficient, precise and flexible processing of cables and wires – ideal for the production of cable harnesses and individual cable looms.

Our services include:

- Cable assembly: We manufacture your wires with millimeter precision and fit them with ferrules. We can process wires with a cross-section of 0.5 mm² to 6 mm² fully automatically and guarantee fast and error-free production.

- Core printing: We offer precise and durable core printing in black or white for clear identification of the cable cores. This printing technology ensures that your cables remain clearly identifiable, even under demanding operating conditions.

- Production of cable harnesses: Whether standard cables or multi-standard cables – we assemble cable harnesses exactly according to your requirements. For complex applications and special customer requests, we offer you individual solutions and guarantee custom-fit production.

- Manual wire end treatment: We carry out manual wire end treatment for special requirements. For example, with flat receptacles or round plugs. In this way, we ensure that your cables are optimally prepared for later use.

Data template for wire harness planning: For efficient planning, we provide you with an Excel spreadsheet in which you can enter your desired wire harnesses and their specifications. We use this data both for preparing quotations and for precise and error-free implementation in production.

With the combination of highly developed technology and precise manual work, we offer you a flexible, reliable and high-quality solution for your cable assembly.

Rely on our expertise to implement your projects efficiently, precisely and to the highest quality. Contact us today to discuss your individual project! We will be happy to provide you with comprehensive advice and a quotation.

Contact person

Marc Winzen

Sales

Phone +49 261 8991 135

Mail marc.winzen@ksv-koblenz.de